Send Us Your

Requirement

Have an project in mind?

Request you to kindly fill all the required details.

Mahindra Plastics Industries

+91-86999-99964

mahindraplastic@ymail.com

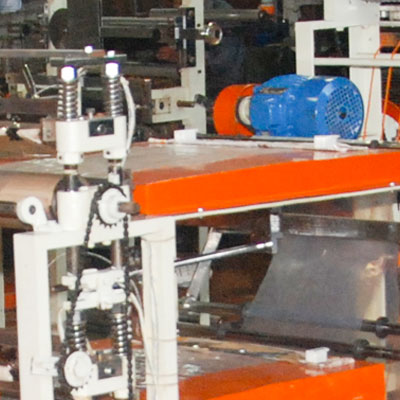

At Mahindra Plastics Industries, we deal in the manufacturing of double-decker sealing and cutting machines. We deal in highly durable, advanced, highly performing, and corrosion-resistant double-decker sealing and cutting machines. It is a machine made for all those looking to make plain or even t-shirt-like bags. It is made for accurate and compact design. While talking about its prices, it is one of the most reasonable machines available.

Mahindra Plastics Industries is one of the leading double deckers sealing and cutting machine services providers. It offers smooth production, as it is made with the conveyor belt. Moreover, it has all the durable and cutting machine, which provides an excellent performance. To meet the client’s requirements, we developed the double-decker sealing and cutting machine today.

Specifications |

455 MM SERVO

BOTTOM |

610 MM SERVO

BOTTOM |

710 MM SERVO

BOTTOM |

810 MM SERVO

BOTTOM |

915 MM SERVO

BOTTOM |

1065 MM SERVO

BOTTOM |

1220 MM SERVO

BOTTOM |

1400 MM SERVO

BOTTOM |

|---|---|---|---|---|---|---|---|---|

Mahindra Plastic

Industries |

455 MM Servo Bottom Sealing & Cutting Machine |

610 MM Servo Bottom Sealing & Cutting Machine |

710 MM Side Sealing & Cutting Machine |

810 MM Bottom Sealing & Cutting Machine |

915 MM Bottom Sealing & Cutting Machine |

1065 MM Servo Bottom Sealing & Cutting

Machine |

1220 MM Bottom Sealing & Cutting Machine |

1400 MM Servo Bottom Sealing & Cutting

Machine |

MIN. FILM WIDTH (in mm): |

63.5 |

63.5 |

63.5 |

63.5 |

63.5 |

63.5 |

63.5 |

63.5 |

MAX. FILM WIDTH : |

406 |

559 |

660 |

762 |

864 |

1016 |

1168 |

1346 |

CUT LENGTH : |

1 Meter |

1 Meter |

1 Meter |

1 Meter |

1 Meter |

1 Meter |

1 Meter |

1 Meter |

LINE SPEED : |

40 Meter |

40 Meter |

40 Meter |

40 Meter |

40 Meter |

40 Meter |

40 Meter |

40 Meter |

TOTAL CONNECTED LOAD : |

8 KW |

8 KW |

8 KW |

8 KW |

8 KW |

8 KW |

8 KW |

8 KW |

Main Motor |

2HP |

2HP |

2HP |

2HP |

2HP |

2HP |

2HP |

2HP |

Servo Motor |

2 KW |

2 KW |

2 KW |

2 KW |

2 KW |

2 KW |

2 KW |

2 KW |

AC Drive Make |

Delta/INVT |

Delta/INVT |

Delta/INVT |

Delta/INVT |

Delta/INVT |

Delta/INVT |

Delta/INVT |

Delta/INVT |

Speed |

160 Strokes per min. according to size and guage of your bag |

160 Strokes per min. according to size and guage of your bag |

160 Strokes per min. according to size and guage of your bag |

160 Strokes per min. according to size and guage of your bag |

160 Strokes per min. according to size and guage of your bag |

160 Strokes per min. according to size and guage of your bag |

160 Strokes per min. according to size and guage of your bag |

160 Strokes per min. according to size and guage of your bag |

Key pad setting/Digital Display |

For Setting Speed, Size, Count with Digital Display Panel Board |

For Setting Speed, Size, Count with Digital Display Panel Board |

For Setting Speed, Size, Count with Digital Display Panel Board |

For Setting Speed, Size, Count with Digital Display Panel Board |

For Setting Speed, Size, Count with Digital Display Panel Board |

For Setting Speed, Size, Count with Digital Display Panel Board |

For Setting Speed, Size, Count with Digital Display Panel Board |

For Setting Speed, Size, Count with Digital Display Panel Board |

Static Eliminator |

3 Static Rods |

3 Static Rods |

3 Static Rods |

3 Static Rods |

3 Static Rods |

3 Static Rods |

3 Static Rods |

3 Static Rods |

Un-Winding Stand for One Roll |

Friction brake, 1

HP A.C. Motor with AC Drive with

sensor On Backside roll on Un-winding |

Friction brake, 1

HP A.C. Motor with AC Drive with sensor On Backside roll

on Un-winding |

Friction brake, 1

HP A.C. Motor with AC Drive with sensor On Backside roll

on Un-winding |

Friction brake, 1

HP A.C. Motor with AC Drive with sensor On Backside roll on Un-winding |

Friction brake, 1

HP A.C. Motor with AC Drive with sensor On Backside roll on Un-winding |

Friction brake, 1

HP A.C. Motor with AC Drive with sensor On Backside roll on Un-winding |

Friction brake, 1

HP A.C. Motor with AC Drive with sensor On Backside roll

on Un-winding |

Friction brake, 1

HP A.C. Motor with AC Drive with sensor On Backside roll

on Un-winding |

SPACE REQUIRED in meters : |

L x W x H = 5 x 2 x 1.5 in meters |

L x W x H = 5 x 2 x 1.5 in meters |

L x W x H = 5 x 2 x 1.5 in meters |

L x W x H = 5 x 2 x 1.5 in meters |

L x W x H = 5 x 2 x 1.5 in meters |

L x W x H = 5 x 2 x 1.5 in meters |

L x W x H = 5 x 2 x 1.5 in meters |

L x W x H = 5 x 2 x 1.5 in meters |

Weight of Machine |

700 Kg approx |

800 Kg approx |

850 Kg approx |

1200 Kg approx |

1100 Kg approx |

1300 Kg approx |

1350 Kg Approx |

1450 Kg approx |

Bottom Sealing and Cutting Machine Manufacturers in India, BOPP tape bag making machine manufacturer in India, BOPP PP LD HM Side Seal Bag Making Machine, Bottom Sealing and Cutting Machine. This product is highly appreciated for its accurate indexing and micro processor control with digital display. This product is manufactured using latest machinery and advanced technology, to ensure high standards of quality.

Are you still having doubts about the double decker sealing and cutting machine ? If yes, reach out to our team and share your worries with us today !

Have an project in mind?

Request you to kindly fill all the required details.

+91-86999-99964

mahindraplastic@ymail.com

Leading Manufacturer of Bag Making Machine, Side Seal Zipper Bag Making Machine & Blown Film Plants Manufacturer in India